Home / Packaging Machinery / Filling Machines

Filling Machines

Packmachine, India's leading manufacturer and importer of packaging machines, offers an extensive range of filling machines for various industries. Our state-of-the-art manufacturing facility located in Bangalore, Karnataka, India, ensures the production of high-quality filling machines that meet international standards.

Our filling machines are designed to provide accurate, efficient and hygienic filling of liquid and semi-liquid products such as juices, milk, sauces, creams, oils, and more. We offer various types of filling machines including volumetric fillers, piston fillers, gravity fillers, and net weight fillers to cater to different product types and packaging sizes.

Our volumetric filling machines are ideal for filling low to medium viscosity liquids while piston filling machines are suitable for thick, paste-like products. Our gravity filling machines are used for filling non-carbonated liquids and our net weight filling machines ensure accurate filling of products by weight.

At Packmachine, we understand that different industries have different filling requirements. Hence, we offer customized filling solutions that meet specific customer requirements. Our filling machines are equipped with advanced features such as touch screen controls, automatic capping and labeling, and remote monitoring to provide maximum efficiency and ease of operation.

Our filling machines are made of high-quality stainless steel, which makes them durable and easy to clean. We also ensure that our filling machines adhere to all safety and hygiene standards, making them ideal for use in the food and beverage, pharmaceutical, and cosmetic industries.

We pride ourselves on providing exceptional customer service, and our team of experienced engineers and technicians are always ready to provide support and assistance. We offer comprehensive after-sales services such as installation, training, and maintenance to ensure that our customers get the most out of our filling machines.

At Packmachine, we are committed to providing high-quality, efficient, and reliable filling machines to our customers. With our extensive warehousing, distribution and transportation network covering Chennai, Coimbatore, Hyderabad, Kochi, Pune and across India, we ensure that our customers receive prompt delivery of our machines.

What are the types of filling machine?

Filling machinery comes in portable tabletop designs or floor standing configurations which can be integrated into food processing and packaging lines, including form, fill seal lines.

Compact, single nozzle machines are used in small, low cost food processing lines. They are suitable for many different foods, including soups, sauces, salad dressings, ready meals, coleslaw, yoghurt, hummus, peanut butter and jam.

Multi-nozzle machines significantly increase throughput capacity by simultaneously filling multiple containers through an increased number of filling heads. Filling heads can be arranged on a rotor (rotary filling) or in a line (linear filling).

How do filling machines work?

Most food filling machines operate with product fed into a hopper then pumped pneumatically or by vacuum, or fed by an auger screw. The product is passed through a nozzle or filler head, with portions measured by volume or weight, into containers and packaging of various types. For some products, the material is fed onto another component of the food product such as bread slices for sandwiches or pie cases.

Manual filling machines are often operated by a hand lever used to pump product through the feeder nozzle. This type of equipment is most suitable for small production facilities, and for locations where electric supply or compressed air is not available for pumping the product. Manual filling machines are more accurate and less prone to spillage than pouring or portioning the product by hand.

Semi-automatic filling machines are usually operated by pumps driven by compressed air. Filling can be set to repeat, and the machinery will offer greater speed and accuracy than manual filling machines. Precise portions can be filled through accurate measuring and dosing equipment incorporated in the weighing or volumetric controls.

Automatic food filling machines feature controls and inline equipment which manages the filling process from material handling, loading, dosing and packaging. The equipment is often scalable with the ability to increase the number of filling heads. Automatic filling solutions offer larger scale operations high throughput and optimum efficiency.

As with all food processing machinery, hygiene is critical, and ease of disassembly for cleaning is an important design consideration.

Explore our range of filling machines

Liquid Filling Machine

Whether you are an artisan company looking for your first automated filling machine or a large organisation with years of experience, PACKMACHINE have solutions to suit the food, beverage, cosmetics, chemical and pharmaceutical industries.

Check out all of our Liquid Filling Machine

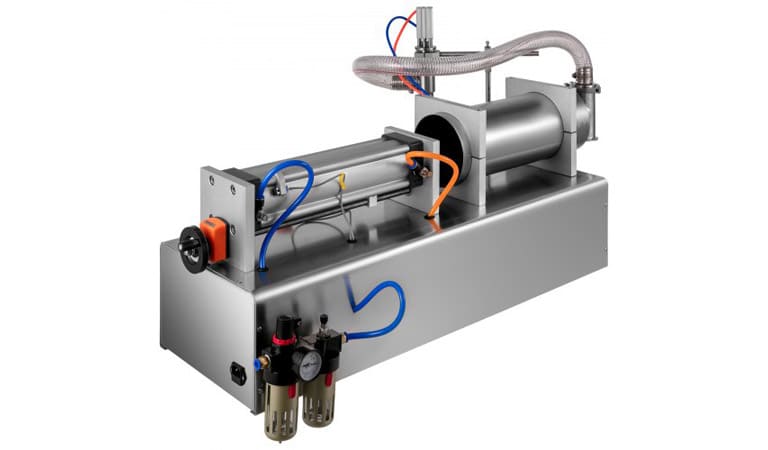

Paste Filling Machine

Discover mesmerizing paste filling machine ranges at PACKMACHINE and select the most befitting option for your facility. The paste filling machine do not require complicated maintenance procedures for optimal usability. They are easy to install, clean, and repair in the eventuality of a breakdown. Because the paste filling machine complying with high-level standards that guide industrial operations, any purchase you make rewards you with top-notch products. The speed and preciseness of these paste filling machine make the production process timesaving and straightforward, thus, multiply your capacity and profitability. They are compatible with many accessories that boost processes such as packaging and sealing.

Check out all of our Paste Filling Machine