Home / Packaging Machinery / Labeling Machines

Labeling Machines

PACKMACHINE, India's leading manufacturer and importer of packaging machinery, offers high-quality labeling machines that meet the needs of various industries. With state-of-the-art manufacturing facilities in Bangalore, Karnataka, PACKMACHINE produces reliable and efficient labeling machines for customers across India and beyond.

At PACKMACHINE, we are committed to providing innovative and cost-effective labeling solutions to our customers. Our team of experienced professionals designs and develops labeling machines that are durable, easy to operate, and deliver excellent performance. We use only the highest quality materials and components in the manufacturing process to ensure our machines can withstand even the toughest working environments.

Our range of labeling machines includes automatic labeling machines, semi-automatic labeling machines, and customized labeling machines. Our automatic labeling machines are designed for high-speed production lines, ensuring accurate labeling with minimal downtime. Our semi-automatic labeling machines offer versatile labeling options and are ideal for small to medium-sized production runs. We also offer customized labeling machines that are tailored to meet specific customer requirements.

At PACKMACHINE, we understand that customer satisfaction is the key to our success. That's why we offer excellent after-sales support and maintenance services to ensure that our customers get the most out of our labeling machines. Our team of highly trained technicians is available to provide technical support, repairs, and maintenance services to our customers.

PACKMACHINE also offers a comprehensive range of labeling materials, including self-adhesive labels, holographic labels, and more. Our labeling machines can handle a wide range of label materials, ensuring that our customers have the flexibility to use the labeling material of their choice.

With a nationwide network of dealers and distributors, we are committed to providing our customers with the fastest possible delivery of our labeling machines. Our warehousing, distribution, and transportation network covers Chennai, Coimbatore, Hyderabad, Kochi, Pune, and other major cities across India.

In conclusion, if you're looking for reliable and efficient labeling machines for your business, PACKMACHINE has got you covered. Our high-quality labeling machines are designed to meet the needs of various industries and offer excellent performance and durability. With our commitment to customer satisfaction, excellent after-sales support, and nationwide network of dealers and distributors, PACKMACHINE is the ideal partner for all your labeling needs.

Types of Labeling Machines

Labeling machines come in many different types to meet the specific needs of various industries. Some of the most common types of labeling machines include:

- Roll Fed Labelers: This type of labeling machine uses a roll of pressure-sensitive labels that are dispensed onto products as they move down a conveyor belt. Roll fed labelers are often used for high-volume labeling operations and are ideal for round or cylindrical containers.

- Wrap Around Labelers: Wrap around labelers are used for labeling flat or rectangular products, such as boxes or packages. The label is wrapped around the product and applied using a combination of heat and pressure.

- Pressure Sensitive Labelers: Pressure sensitive labelers use a adhesive label that is applied to a product using pressure. They are ideal for products that are delicate or have irregular shapes, as the pressure-sensitive label will conform to the shape of the product.

- Shrink Sleeve Labelers: Shrink sleeve labelers apply a sleeve label to a product, which is then shrunk using heat to form a tight fit. Shrink sleeve labelers are often used for labeling irregularly shaped products, such as beverage bottles or tubes.

Benefits of Labeling Machines

Labeling machines offer numerous benefits to businesses, including:

- Increased Production Speed: Labeling machines can apply labels to products much faster than manual labeling, reducing the time needed for the labeling process and increasing overall production speed.

- Improved Label Accuracy: Labeling machines are designed to apply labels accurately and consistently, reducing the risk of human error and ensuring that all products are labeled correctly.

- Streamlined Packaging Process: Labeling machines can integrate with other packaging equipment, such as conveyor systems, to streamline the overall packaging process.

- Reduced Labor Costs: Automating the labeling process with a labeling machine can reduce the need for manual labor, leading to significant cost savings for businesses.

Choosing the Right Labeling Machine

When choosing a labeling machine, it's important to consider factors such as production volume, product size and shape, and labeling requirements. Other factors to consider include the type of label being used, the type of product being labeled, and the overall budget for the labeling machine.

A reputable labeling machine manufacturer can help you choose the right labeling machine for your specific needs and provide ongoing support and maintenance to keep your machine running smoothly.

Streamline your packaging process with a high-quality labeling machine from a trusted manufacturer. Contact us today to learn more about our labeling machine options and how we can help you improve your packaging process.

Branding and Promotional Labels

Labels are used on every kind of product to brand and decorate packaging to communicate brand identity and motivate consumer purchase. There are multiple options for brand owners to choose from, including different substrates, embellishments and customisation, as well as a range of quality levels and finishes.

Information Labels and Barcode Labels

Many labels contain pre-printed barcodes supplying batch, stock and price information to the retailer and consumer. Other machines provide print-on-demand and weigh/price labels, usually for fresh or perishable products where the weight of item varies from pack to pack or for transit purposes. Many of these labels are printed and applied in the store or warehouse.

Tamper-proof Labels

Labels are also used to provide protection against tampering to ensure the product reaches the consumer unopened and without interference. Sleevers or sleeving equipment, which apply a sleeve of thermoformable or stretch material to the neck or body of the container, are generally used to apply tamper-evident labels. Shrink-sleeve labels are also used on products which do not have surfaces suitable for a conventional label.

Security Labels

A growing market is security labeling to counter fraud and theft, and give brand protection and authentication. These include RFID and smart labels, holographic labels, tamper evidence, counterfeit deterrence and source tagging. Other machines are used to apply leaflet labels – multi-page labels that provide space for large amounts of consumer information, e.g. in pharmaceutical applications.

What are the types of labeling machines?

Wet Glue labeling Machines

Wet glue labeling machines apply labels using a glue which is liquid at room temperature. These machines usually apply labels from a stack to rigid containers, such as beer or spirit bottles at very high speeds.

The machines are particularly suitable for wet environments, such as liquid filling of beverages where they continue to be the predominant application method. Often the labels are highly decorative and can be embossed and cut into complex shapes, or are applied to difficult container shapes. Often more than one label is applied to one container, requiring several applicators.

Since the 1960s, Pressure Sensitive labels have become more popular for most other types of applications. They are used extensively in the beverage sector.

Hot Melt Label Applicators

Machines which apply labels using adhesive which is solid at room temperature.

Hot melt label applicators are a variant of the Wet Glue Labeller, where different types of adhesive are heated to a liquid state prior to application. The adhesive may vary due to the product, packaging material or external conditions in the packaging area. This type of applicator is, for example, used for wraparound labels that cover most of a container body and wall surface.

Pre-Gummed Label Applicators

These machines apply labels which are pre-coated with glue. The gum label is passed through a water reservoir or sprayed with water to make the adhesive stick. These machines are no longer commonly in use.

Pressure-Sensitive Self-Adhesive Label Applicators

Pressure-sensitive labeling machines use pre-glued labels supplied on a reel of release paper or film. They require no water to make the adhesive stick.

Due to their popularity, they have replaced many traditional forms of wet glue application. The advantages are that there is no liquid glue or heat required in the process and the label can be made from materials other than paper. The labels can be pre-cut into complex shapes on the reel by means of a die-cutter and stored on the reel until required, with minimal risk of damage. This method of application enables labels to be applied at medium/high speed to soft packages, as well as rigid containers and where the product could be damaged by water or heat.

Heat-Seal Label Applicators

Heat Seal Label Applicators apply pressure sensitive labels coated with a heat sealable material.

Print & Apply Label Applicators

Print and Apply labeling machines can be loaded with information which is used to print labels on demand with details including batch number, production date, weight, price and transit data, as well as simple graphics.

Common forms of Print & Apply Labeller are those used by retailers to print weight and price information at the point of sale. Products such as meat, fresh fruit and vegetables and other types of product which are not pre-packed prior to arriving in the supermarket use this method of labeling. Often the labels include a barcode for scanning at the checkout.

Print & Apply labeling equipment is also used in warehousing and distribution to provide delivery, batch and other transit information. This allows the product to be traced, and can confirm that the product has arrived where it should, on the correct date and in the right quantity. The label can be printed directly on to the outer transit container or on to a label which is then applied to the transit container. Information can be printed in both standard type and as a barcode.

Let our high quality strapping tools do the hard work for you

Battery Powered Strapping Tools

Easy to operate high performance friction weld battery powered hand strapping tool with vertical and horizontal applications and on uneven surfaces. The strap is tensioned, sealed and cut quickly and efficiently. The advanced and pre-programmed adjustable tensioning force control panel allows tension and sealing time to be set precisely for soft, medium or high tension settings.

Read more

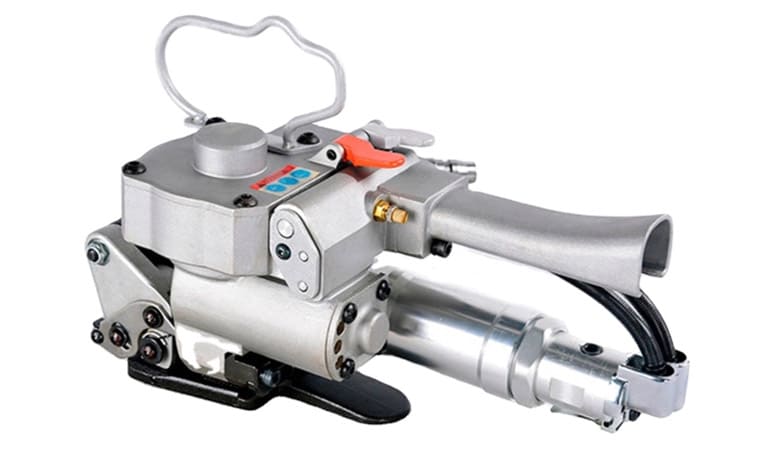

Pneumatic Strapping Tools

We sell only high-quality but affordable pneumatic strapping tools for PET (polyethylene) and PP (polypropylene) strap for all kinds of sizes from 13 till 19mm. Pneumatic banding tools have ISO and other needed certificates. All pneumatic strapping tools have a 12-month warranty. Service is in India. If something is wrong with the pneumatic strapping tool we perform a service and send you a replacement pneumatic strapping tool for that period.

Read more

Manual Strapping Tools

Packing work is tedious and time-consuming, and the packing effect is satisfied without a professional tool. Thus, we offer you this manual strapping tools, including a tensioner, a sealer, a coil of banding, and metal seals. This kit is a good helper for you when packing.

Read more