Home / Packaging Machinery / Stretch Wrapping Machine / Semi Automatic Stretch Wrapping Machine

Semi Automatic Stretch Wrapping Machine

Welcome to PACKMACHINE, the leading provider of packaging solutions for businesses of all sizes. We are proud to offer our Semi Automatic Stretch Wrapping Machine, an innovative and reliable solution for wrapping pallets of goods quickly and efficiently.

Our Semi Automatic Stretch Wrapping Machine is designed to make the wrapping process simple and efficient, reducing the time and labor required to prepare pallets for shipment or storage. This machine features a durable construction and user-friendly design that makes it easy to operate, even for inexperienced users.

The Semi Automatic Stretch Wrapping Machine from PACKMACHINE features advanced technology that ensures consistent wrapping quality and reliable performance. This machine can wrap pallets of various sizes and shapes, making it an ideal choice for businesses with diverse packaging needs.

One of the key benefits of our Semi Automatic Stretch Wrapping Machine is its ability to save time and reduce labor costs. By automating the wrapping process, businesses can streamline their packaging operations and increase productivity. This can lead to significant cost savings over time, allowing businesses to allocate resources to other areas of their operations.

In addition to its efficient operation, the Semi Automatic Stretch Wrapping Machine from PACKMACHINE is also designed to be safe and easy to use. This machine features a variety of safety features that protect users and ensure that the wrapping process is carried out in a secure and reliable manner.

At PACKMACHINE, we are committed to providing our customers with the best packaging solutions on the market. Our Semi Automatic Stretch Wrapping Machine is just one example of our commitment to quality, reliability, and customer satisfaction.

If you are looking for a reliable and efficient solution for wrapping pallets, look no further than the Semi Automatic Stretch Wrapping Machine from PACKMACHINE. Contact us today to learn more about this innovative machine and how it can benefit your business.

6 Advantages of a Semi-Automatic Stretch Wrapping Machine

Thinking about making the switch from arduous hand-wrapping to machine wrapping? Or are you simply looking for new and improved equipment for your warehouse or distribution center? Here are six advantages of semi-automatic stretch wrapping that showcase why semi-automatic stretch wrappers are a must-have for any packaging facility.

Reduce Film Consumption

If you are wrapping more than 10 loads per day, it makes sense to automate. Using a semi-automatic stretch wrapper can help your business cut down on film costs. This is mainly due to pre-stretch technology. Pre-stretched film is film that’s been stretched to to get the most out of the film based on the pre-stretch gear setting. For example, if you are using 300% pre-stretch, you are taking one foot of film and turning it into four feet of film. Pre-stretch film has better memory, is more durable, provides a uniform stretch, is easier to apply, and eliminates neck down. This helps your business get the most out of each roll of film.

Reduce Repetitive Motion Injuries

The next advantage of semi-automatic stretch wrapping is that it can reduce on-the-job injuries. The repetitive motions of hand-wrapping can cause considerable strain on your employees’ backs, arms, and legs. Since semi-automatic stretch wrappers wrap loads in lieu of human workers, you can say goodbye to injuries caused by load wrapping.

Reduce In-Transit DamageLess product damage translates into less time and money spent and leads to a considerable boost in customer satisfaction. A semi-automatic stretch wrapper will wrap your loads with the correct containment force every time, which keeps them protected against dirt, dust, moisture, and impact damage.

Improved Load Stability

The main reason we use stretch wrap is to unitize loads for shipment. Unitizing loads for shipment makes products easier to transport and ship. It also protects individual products from damage. But how do you unitize loads efficiently? Using a semi-automatic stretch wrapper is the best way to unitize and stabilize loads. Unlike hand wrapping where consistency will vary from load to load, these machines wrap pallet loads consistently every time and ensure your products will remain safe and secure during transit.

Reduced Labor Costs

A new machine always requires an upfront investment. But this investment is worthwhile when you know the machine will save you money in the long run. As mentioned before, if you are hand wrapping 10 loads or more per day you need to automate. Because semi-automatic stretch wrappers require minimal human intervention, you can reduce or repurpose labor that would otherwise be used to hand-wrap loads.

Increase Throughput Capabilities

Semi-automatic stretch wrappers can increase your business’s throughput capabilities, which means you can process significantly more units per hour and per day. Semi-automatic stretch wrappers are much faster and more accurate than human workers.

Wrap and secure pallets quickly with our semi automatic stretch wrap machines

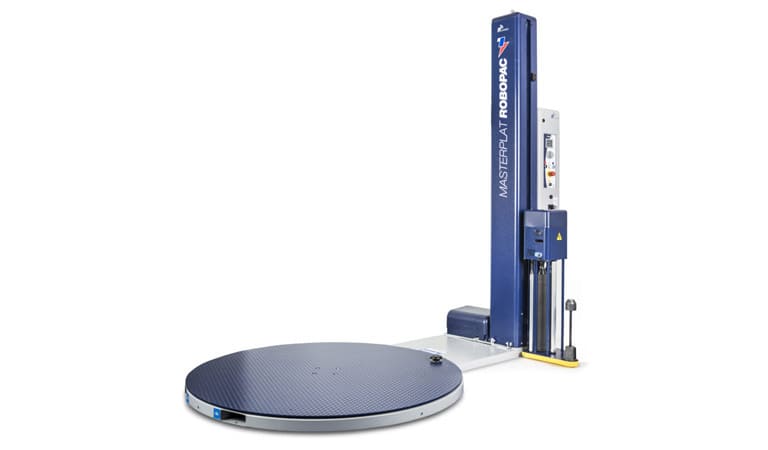

Masterplat Plus Semi Automatic Stretch Wrapping Machine

The Robopac Masterplat Plus PGS Pallet Wrapping Machine has a user-friendly panel for ease of use. Performance-wise, it offers excellent value for money. Turntable machines are ideal for wrapping high volumes of pallets, and they wrap them in seconds. If you are looking to increase your productivity, you should consider a turntable Pallet Wrapping Machine.

Check out our Masterplat Plus Semi Automatic Stretch Wrapping Machine